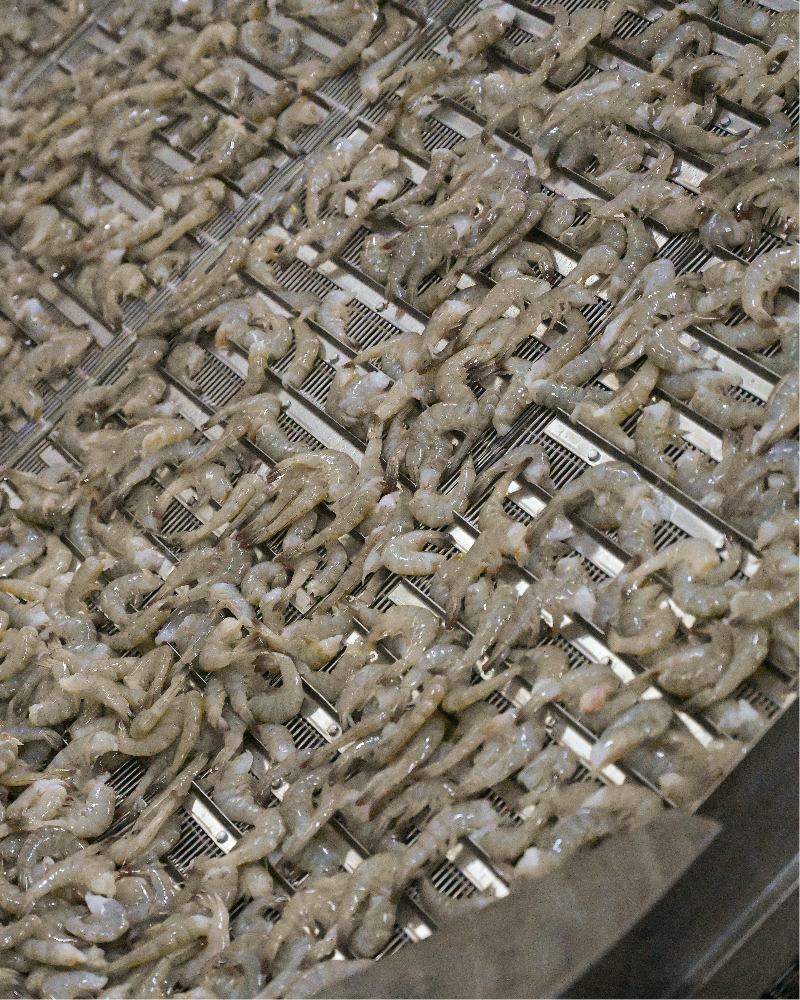

Processing

Fedora Sea Foods has established itself as a vertically integrated company in the aquaculture industry by launching an advanced, state-of-the-art shrimp processing and export facility. Since 2021, we have been supplying shrimp consumers worldwide with a diverse range of high-quality, antibiotic-free shrimp, all while strictly adhering to international food safety standards.

We operate using a farm-to-fork model that guarantees complete traceability of all our products. With the support of our own farms, hatchery, and feed, we maintain greater control over our supply chain and the quality of materials sourced for production. In addition to our internal resources, we have built a vast network of regular suppliers across the country, ensuring uninterrupted production and timely deliveries to consumers globally.

Our processing facility is equipped with cutting-edge technology and imported machinery that are compliant with the latest international standards. It features twin IQFs and 4 plate freezers, each capable of producing over 40 MT and 35 MT daily. The cold storage facility is designed to accommodate up to 2,100 Metric Tons.

We offer a variety of raw frozen shrimp catering to the specifications and requirements of our customers. A few products are listed below:

Raw White Shrimp

| 1. HeadOn | 6. Butterfly 90% |

| 2. Headless | 7. Nobashi Shrimp |

| 3. Headless – Easy Peel | 8. Pin Peeled & Deveined |

| 4. Peeled & Deveined – Tail On | 9. Vacuum Packed |

| 5. Peeled & Deveined – Tail Off | 10. Broken Shrimp |

Skewers

| 1. Raw Peeled & Deveined – Tail On |

| 2. Raw Peeled & Deveined – Tail Off |

| 3. Marinated skewers with custom flavours. |

Black Tiger Shrimp

| 1. Head On | 3. Peeled & Deveined – Tail On |

| 2. Headless | 4. Peeled & Deveined – Tail Off |

Quality Control & Assurance

At Fedora, we ensure that our quality control procedures are regularly evaluated and comply with the standards established by leading global aquaculture and food safety organizations, including BAP, HACCP, IFS, FSSC22000 and a few others. We ensure extensive testing is done to guarantee our products comply with food safety standards.

We conduct testing and monitoring on every batch of our products at all stages, including assessing our raw materials during the pre-harvest phase and our finished goods. This is all carried out at our in-house lab, which adheres to international equipment standards and employs only certified and government-approved food technologists and microbiologists.

We classify the parameters we test into three categories: Antibiotics, Microbiological, and Organoleptic. We perform the usual organoleptic tests that are followed by antibiotic tests. For antibiotics, we test all batches for AHD, AOZ, SEM, AMOZ, and CAP, in addition to salt and sulphite content. The biological testing covers a range of bacterial tests, including Salmonella, Listeria Monocytogenes, Vibrio cholerae, Vibrio Parahaemolyticus, Coliform Bacteria, Escherichia Coli, Total Plate Count, and Staphylococcus aureus.

Recognised by the World’s Leading Certification Bodies.

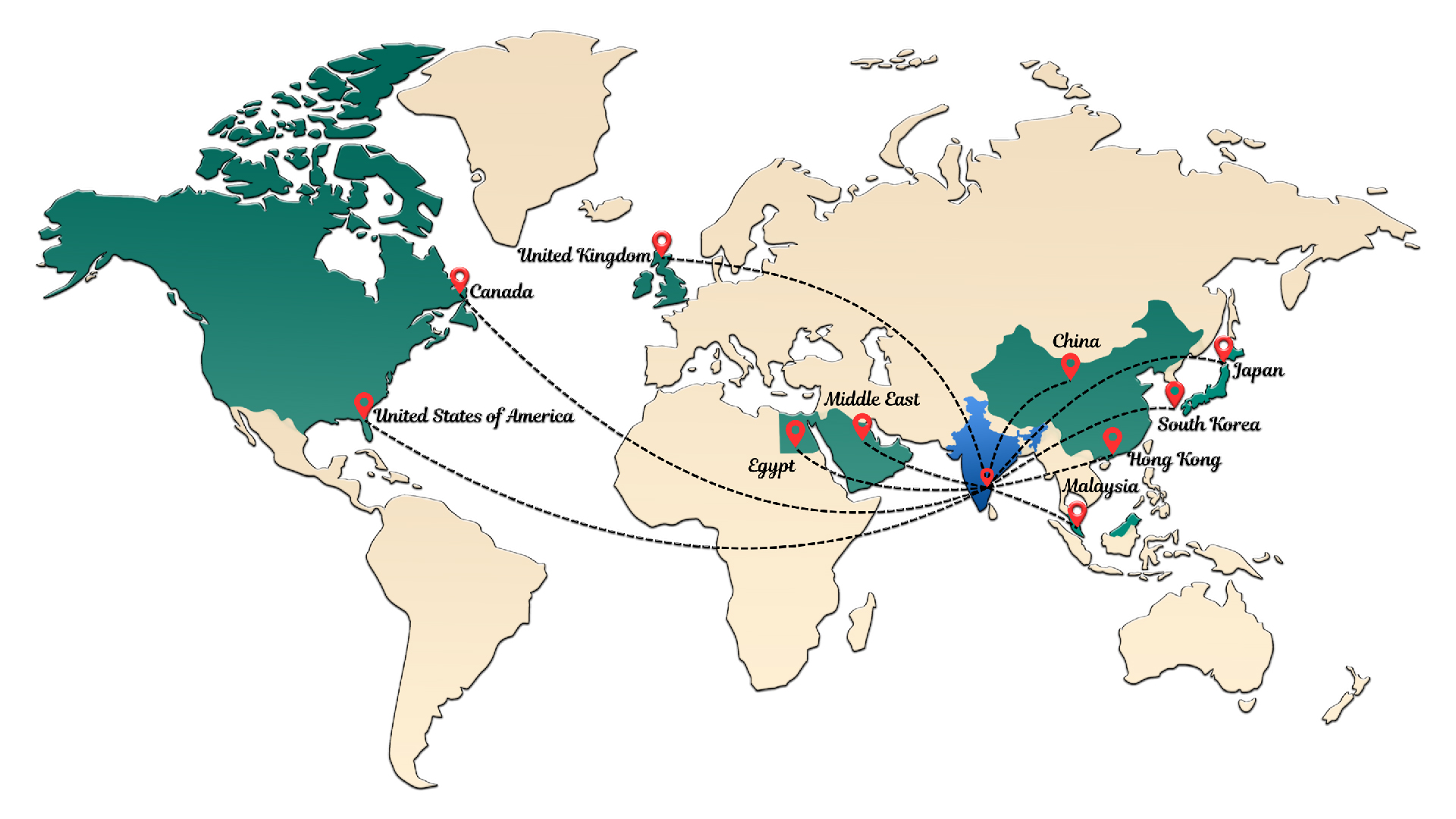

Our Export Footprint